ABOUT

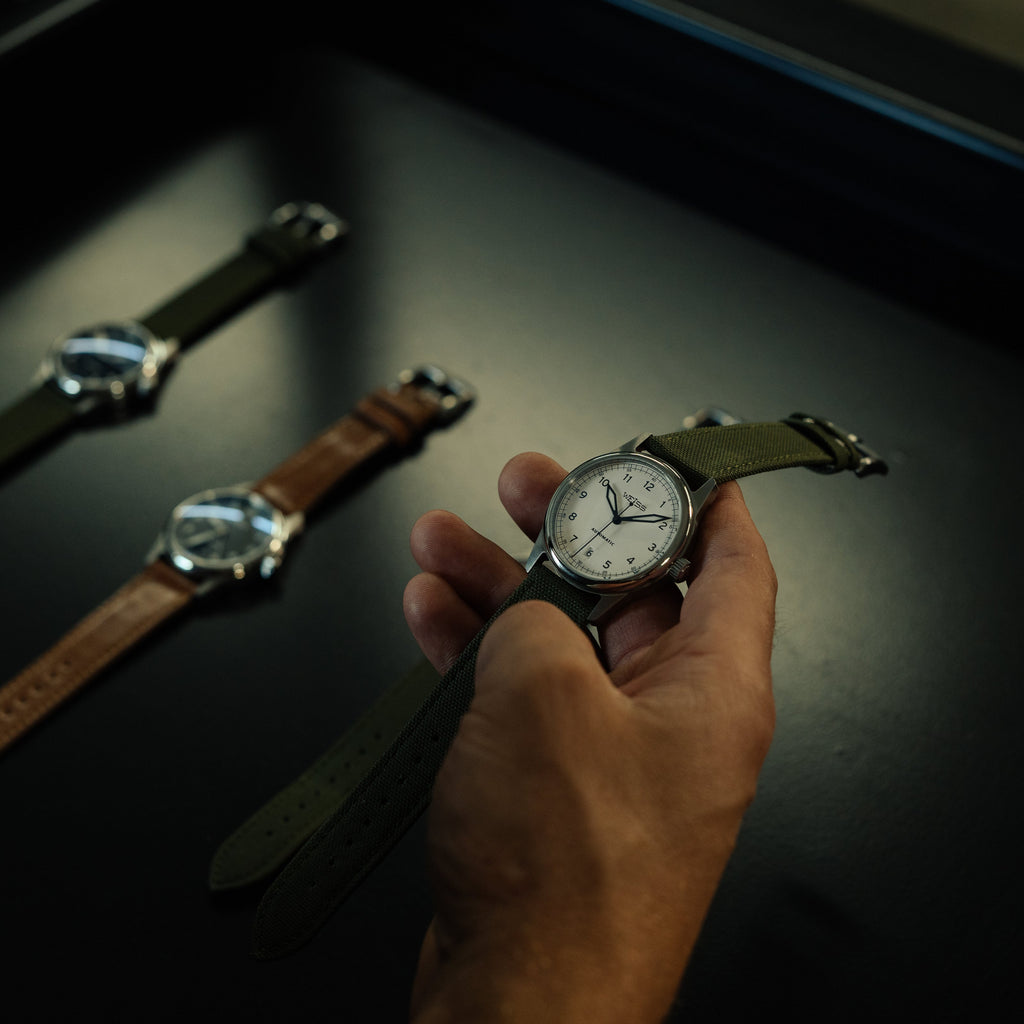

Weiss Watch Company revives the art of American watchmaking in Nashville, crafting timepieces to accompany you on life’s most meaningful journeys.

AMERICAN WATCHMAKING

Weiss Watch Company brings true watchmaking back to American soil. From our Nashville studio, the only open atelier of its kind in the United States, every timepiece is finished and assembled by hand in extremely limited quantities. Each timepiece is a testament to craft, rarity, and the belief that objects made with care carry a legacy all their own.

A MODERN STUDIO OF CRAFT

Inside our Nashville studio, traditional tools sit alongside modern precision machining. Cases are finished by hand, dials crafted with care, and movements hand-finished, assembled, and regulated at the watchmaker’s bench. Scarcity is inherent in work done entirely by hand, which is why only a limited number of Weiss timepieces can be created each year.

THE VISION

Cameron Weiss trained in both the United States and Switzerland, beginning his brand with a commitment to American craft. A graduate of the Nicolas G. Hayek Watchmaking School and holder of the esteemed WOSTEP certification, he honed his skills at Audemars Piguet and Vacheron Constantin before founding Weiss Watch Company in Los Angeles in 2013.

He later relocated to Nashville to continue reviving an art once thought lost in America. His vision is simple: to build honest, timeless timepieces with the patience and discipline of a watchmaker, not the speed of a factory.

AT THE WATCHMAKER'S BENCH

Each Weiss timepiece is produced in small batches and individually assembled in Nashville. The movements are developed for Weiss to suit each model’s purpose, mechanical calibers valued for their reliability and character, composed of both domestic and carefully sourced components.

Every movement is hand-finished, assembled, and regulated at the watchmaker’s bench. The result is a timepiece built for daily wear and destined to be treasured for generations with proper care; each timepiece is one of only a limited number created each year.

A LEGACY IN MOTION

From Nashville, our watches travel the world. Our timepieces are chosen by collectors and connoisseurs who value authenticity over excess. To own a Weiss is to join a rare story of American watchmaking, preserved and reimagined for a new era.